Rhodes Corporate Park, Building B, Ground Floor, Suite 4, 1 Homebush Bay Drive, Rhodes NSW 2138. Tel : Office 02-8054-7000

FOR CUSTOMER SERVICE

COPYRIGHT(C)MEGA’GEN IMPLANT CO.,LTD.ALL RIGHTS RESERVED

This is the reason for Trust & Quality

Trust & Quality is the certificate of Implant Foundation.

Highest quality made with proven materials and advanced technology.

This is the reason for Trust & Quality

MegaGen Implant has the technology and know-how to manufacture the highest quality of the products in all processes from raw material selection to packaging.

MegaGen Implant guarantees to provide you with perfect products through carefully selected raw materials, automation technology, and repetitive inspections.

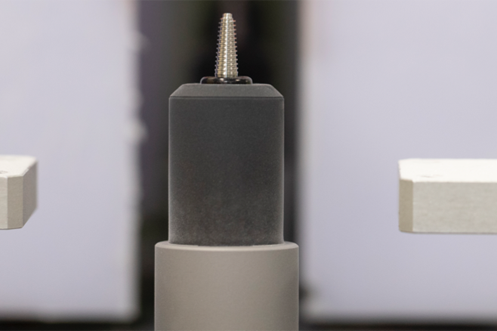

Materials

Pure titanium (F-67) used for fixtures & titanium alloys (F-136) for dental prosthetics, as approved by American Society for Testing & Materials (ASTM) & U.S. FDA

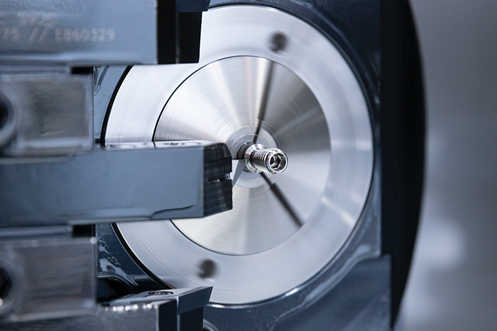

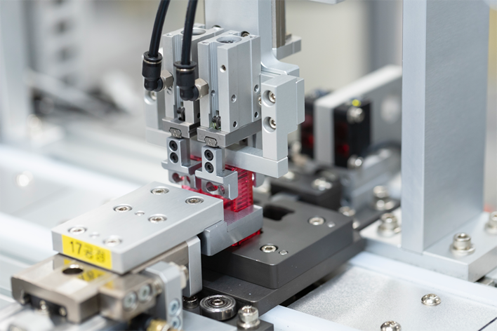

Mechanical Working)-CNC

Titanium milled with precise dimensions & shaped using CNC multifunction machines

Cleaning

- Removal of foreign substances & possible contaminations after each process

- Performed up to five times depending on product characteristics & manufacturing process

- Periodic cleaning validation (twice a year) to maintain product safety

- Vacuum cleaning of fixtures performed twice using 100% distilled water

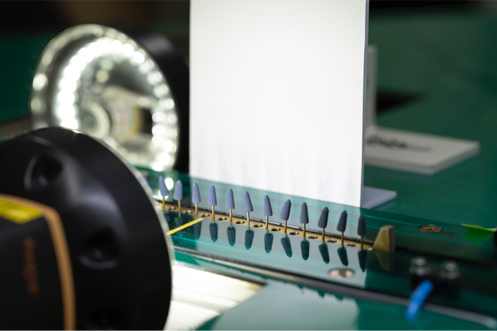

Inspection

- Process inspection to check dimension, shape, & function after machining

- Etching inspection to check safety (acid residue) after etching process

- Final inspection before product packing

- Shipment inspection to match product labels after final packing

- Independent inspection by special inspectors during machining process

Anodizing

- Electrochemical method of controlling oxide film for product identification & esthetics

- Small (purple), regular (blue), wide (yellow), & super wide (green)

Etching

- Surface corrosion to create SLA(Sandblasted Large grit, Acid-etched) surface with increased roughness of Ra 1.5㎛ to 2.5μm

- Self-cleaning process of equipment for safety & SEM analysis of all batches

Sanding

Sandblasting to create RBM surface with increase roughness of Ra 1.5 ~ 2.5 ㎛.

Xpeed

CaTiO3-incorporated layer formed by fusing Ca ions to fixture surface

Marking

- Laser markings used for product function (drill lines) and identification (standard sizes & reference codes)

- Performed in-house to maintain excellent quality control

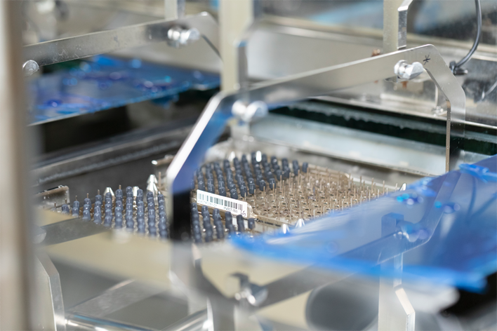

Packing

Implant Manufactured products are packaged in an automated process.

Sterilization

- Short-wavelength gamma-ray sterilization of all MegaGen implants

- Performed by U.S. FDA-registered company

- Confirmed by special stickers that change from orange to red during gamma-ray sterilization process

Logistics

Fully-automated advanced logistics system used to ship MegaGen products worldwide to make sure you receive your products on time