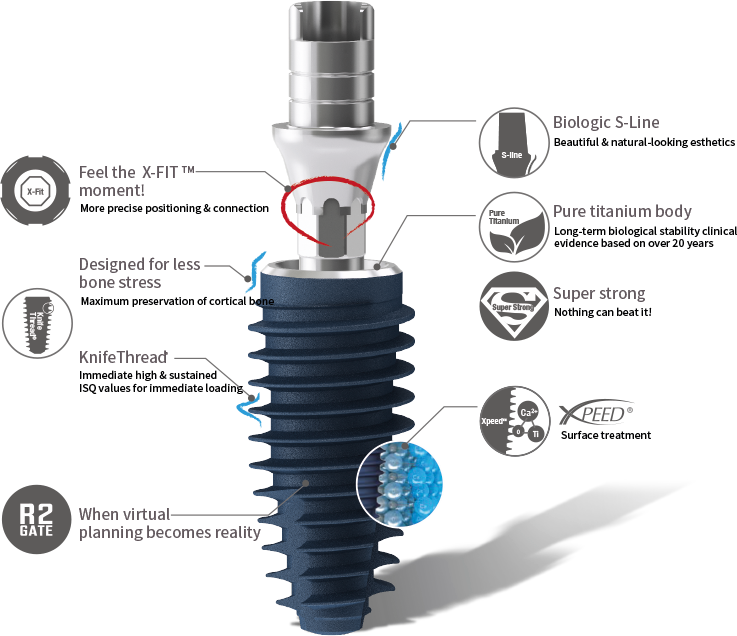

Key Advantages

- Incorporating key features of an AnyRidge® implant

- Higher compressive & fatigue strength with long-term biological stability

- Accurate positioning & excellent prosthetic connection (X-Fit™)

A NEW ADDITION

TO THE ANYRIDGE® FAMILY.

Despite its growing popularity amongst users and the continuing build up of clinical evidence showing the benefits of the AnyRidge® implants both for patients and for doctors, some clinicians still hesitate to turn to it. Habitual use of old-style implants, or standard techniques make them unwilling to try something so uniquely different. To enable all clinicians to adopt the “best implant in the world”, we have extended the AnyRidge® Family.

AnyRidge® Makes a Difference

Bone destroyer or Bone friendly implant?

The new AnyRidge® Octa1 implant makes it possible for all clinicians to take the opportunity to offer their patients the advantages of AnyRidge®.

Having a slightly different implant body shape and connection but incorporating many of the key features of the AnyRidge® implant, Octa1 offers a simple solution for clinicians wishing to offer the best to their patients without making big changes to their current surgical protocols.

KnifeThread ® guarantees sustained implant stability

Thanks to MegaGen’s unique KnifeThread® and super self-tapping design, better initial stability can be attained in any compromised bone situation. The design enables bone condensing, gentle ridge expansion, maximized compressive force resistance, and minimized shear force production.1

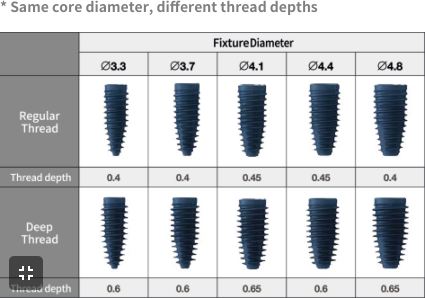

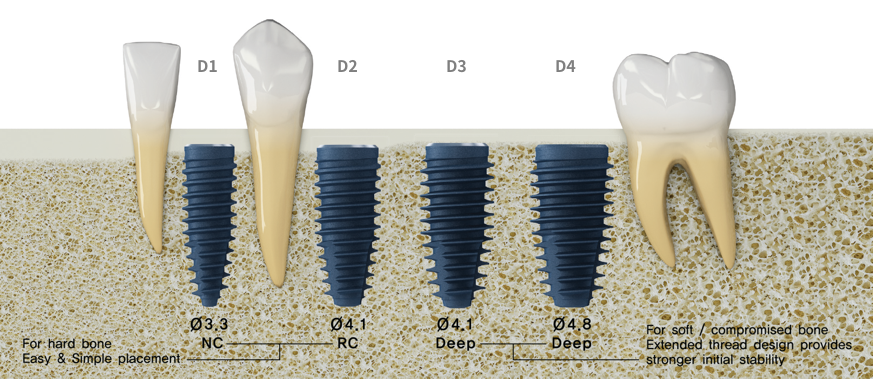

Two simple options for better initial stability

- Regular Thread for hard bone Easy & simple placement

- Deep Thread for soft/compromised bone Extended thread design provides stronger initial stability

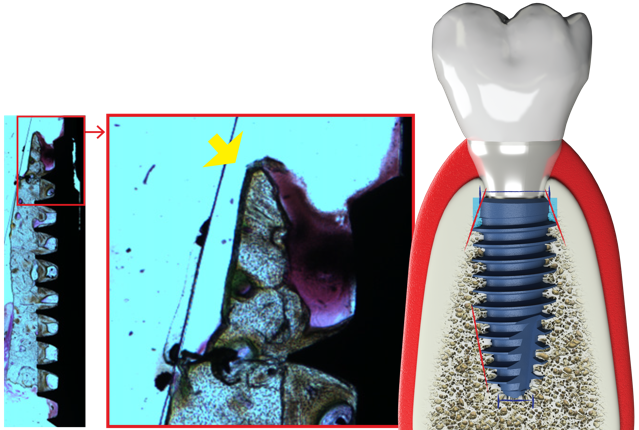

Maximum preservation of cortical bone

No dependence on cortical bone for initial stability; decreased stress on cortical bone helps to prevent bone resorption after implantation.

Advanced coronal design allows maximum cortical bone preservation around implants. 6,7

* More cortical bone

= more soft tissue volume

= beautiful gingival line

• Human Biopsy (2.5 years after placement)

Sharp & high alveolar crest is maintained thanks to biologically-inspired implant design

Maintenance of alveolar bone means peri-implant marginal gingiva shows almost no recession at 2.5 years follow-up, even with limited ridge width

- Strong

- Faster

- Safer

To promote secondary stability, all AnyRidge® Octa1 implants have a special extra surface coating called Xpeed. This unique hydro-thermal incorporation of calcium ions has already been proven to activate osteoblasts and accelerate osseointegration, essential for secondary stability.4,5

Plus, Xpeed provides an important quality check to avoid any acid residue (BLUE means NO acid residue!)

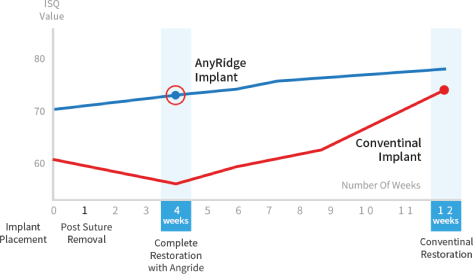

Complete final prosthetics in ONLY 4 weeks

Most importantly, the resulting initial stability of AnyRidge® implants is usually high, as measured by the Implant Stability Quotient (ISQ) and insertion torque (IT). As a guide, an ISQ ≥ 60 and IT ≥ 45 N/cm are required for immediate functional loading.

In contrast to other implant systems, the ISQ values for AnyRidge® implants are maintained or increase over time, indicating fast osseointegration and effective secondary stability.

Higher compressive & fatigue strength with long-term biological stability

AnyRidge ® Octa1 fixtures are made of pure cold-worked medical-grade 4 titanium to ensure high compressive & fatigue strength for long-term biological stability.

The overall strength of the implant system has been improved by optimizing (i) the thickness and external shape of the fixture and abutment, (ii) the contact area between the fixture and the abutment, (iii) the abutment screw design and diameter, and (iv) the choice of titanium material.

Stronger than a strong implant

Clinical evidence over 20 years consistently supports the biocompatibility & long-term success of pure titanium implants. The morphology of the AnyRidge® Octa1 implant in conjunction with Ti grade 4 has shown a higher compressive & fatigue strength than B implant system with Ti-alloy.

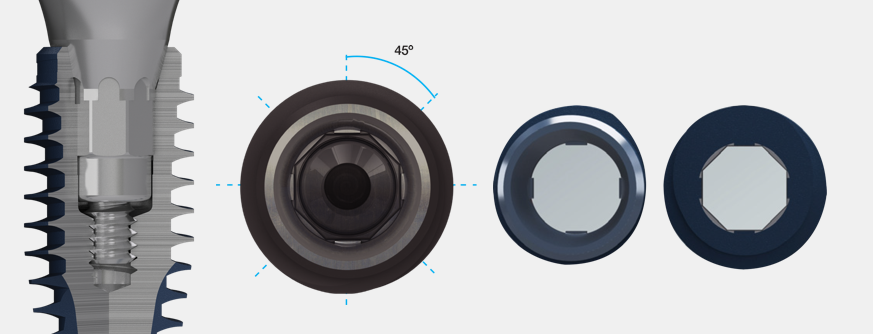

Feel the X-FIT™ moment!

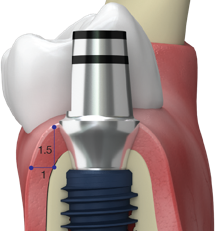

AnyRidge® Octa1 has a unique X-FIT™connection with a 15° internal conical connection & double-fastened internal structure creating a keystone arch & octa combination

Accurate positioning & excellent prosthetic connection

Long-term mechanical stability & minimized biologic width

Watch X-FIT™

- AnyRidge® Octa1 indexed prosthetics CLICK into place

8 possible prosthetic positions facilitate more precise positioning on angled abutments. AnyRidge® Octa 1 prosthetics are easily tightened when engaged with a CLICK! - Hermetic seal & long-term mechanical stability

Helping to maintain healthy crestal bone - AnyRidge® Octa 1 connection & prosthetic option

offers excellent solution for multi-unit restorations

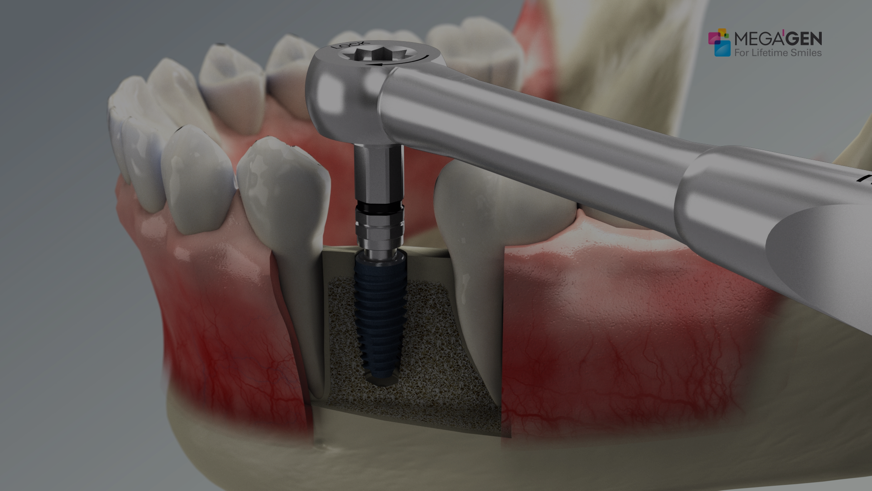

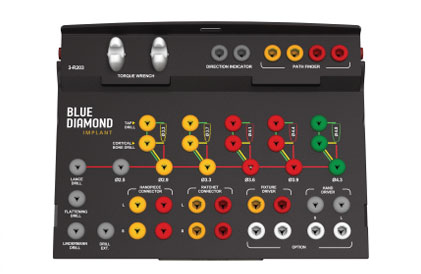

Simple & intuitive drilling sequence

AnyRidge® Octa 1 fixtures achieve optimum initial stability when used with a guided drilling sequence.

Surgery is simplified with a clear drilling protocol based on fixture diameter and bone density.

① Check fixture diameter to be inserted, colored rings indicate line-up of drills suitable for each fixture diameter

② Drilling sequence for each bone type is identified by color D3: red / D2: yellow / D1: green /D4: drill to previous stage of D3

③ If bone density or initial stability is not good enough, place a deep thread fixture with the same diameter & length as a normal thread implant using the same drill sequenc

Functional abutment design for excellent soft tissue response

A better peri-implant biotype & better emergence profile are assured due to a double offset structure incorporating a thread-less collar on the fixture and S-line cuff design on the prosthetics

Broad prosthetic line-up from conventional to digital restorations

Every case, every shape, every size…everything has been considered to satisfy every clinical need

References

- McCullough JJ , Klokkevold PR The effect of implant thread design on implant stability in the early post-operative period

https://www.ncbi.nlm.nih.gov/pubmed/27699890 - Raquel Zita Gomes, Implant Stability in Posterior Maxilla: A controlled Clinical Trial

https://www.hindawi.com/journals/bmri/2017/6825213/ - Guiseppe Luongo, Immediate functional loading of single implants: A multicentre study with 4 years of follow-up

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5928471/ - S.-Y. Lee, The cytocompatability and osseointegration of Ti implants with Xpeed surfaces

http://www.megagenitalia.it/wp-content/uploads/2017/02/4.-COIR-2011-XPEED.pdf - F.G. Mangano Early bone formation around immediately loaded implants with nanostructured calcium-incorproated and machined surface: a randomized controlled histologic and histophometric study in human posterior maxilla

https://www.ncbi.nlm.nih.gov/pubmed/28154996 - Ueli Grunder Influence of the 3-D Bone-to-Implant Relationship on Esthetics

https://pdfs.semanticscholar.org/0517/97dcac50b8cf3591323421f5ddb6ee794c5e.pdf - Nozawa Biologic ratio of supra-implant mucosa

https://www.ncbi.nlm.nih.gov/pubmed/19655487 - JS Im, SI Yeo, KO Park, JH Lee, TY Kwon Correlation between material & product strength under static & fatigue loads

http://ksdm1966.com/_common/do.php?a=full&b=12&bidx=1013&aidx=13337